Press News

11/25/2020

Baerlocher strengthens its foothold in recycling applications at PRSE Virtual conference

The pastilles can be fed directly into the compactor unit of a film recycling line by using low cost volumetric feeders. The improved quality of the recyclate is then quickly made visible in, for example, a downstream film blowing line, where less gelling and fewer degradation products lead to fewer bubble breakages and a more homogenous mechanical performance of the film. Baerlocher´s Technical Product Manager Henrik Eriksson comments: “Since the K-Show we have gathered a lot more data that show the benefits of our products, which we are now excited to share with recyclers, converters and brand owners at the PRSE Virtual. We want to highlight how our analytical work can provide the tools recyclers need to communicate the higher value of recyclate upcycled with Baeropol additives.” One of the Baeropol T-Blends not only safeguards processability and mechanical properties, but it also makes polypropylene solidify faster and more uniformly in the mold. This enables shorter cycle times and ensure the dimensional stability as the producer moves from batch to batch. Another Baerlocher specialty product is aimed to remedy the supply-and-demand mismatch between low melt strength HDPE from post-consumer waste and high melt strength HDPE for pipe extrusion and extrusion blow molding of large parts. Upcycling low value HDPE

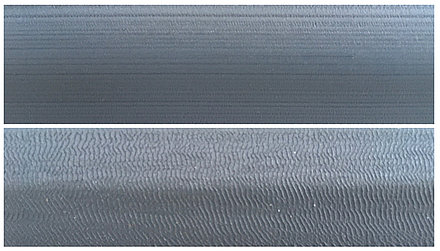

This additive acts as a chain extender and allows a compounder to upcycle low value HDPE for implementation in higher value applications. In customer evaluations it has been shown that modification with this chain extender can rid flow instabilities in recycled HDPE, which cause a rough surface appearance on extruded profiles. The modification is also able to remove the rotational memory effect that can sometimes occur in profile extrusion, i.e. a tendency of the profile to rotate in the direction of the extruder screw as it exits the die. The product is also capable of mitigating negative effects from having a minor part of PP or PE present in one of the two polymers, steering the properties in the direction of the pure majority resin, by acting as a compatibilizer. About Baerlocher:

The Baerlocher Group is a leading manufacturer of additives for the plastics industry. Its portfolio includes a broad range of stabilizers and other additives suitable for a variety of polymer and non-polymer applications. Baerlocher has a strong focus on customer and employee needs and is highly committed to innovation and sustainability. Its pioneering and proactive role is underlined by the support provided to the PVC industry during the transition from lead- to calcium-based stabilizers and by its innovative lubricant systems for wood plastic composites. Baerlocher embraces the principles of responsible care. It operates an ISO 9001 certified quality management system and an environmental management system compliant with ISO 14001. Baerlocher plays a positive role in both the business community and society as a whole. This includes work within industry associations, and the provision of training opportunities in a variety of disciplines. The Baerlocher Group has production plants around the globe and operates a sales network serving all major countries. BAEROPAN, BAEROSTAB, BAEROPOL, BAEROLUB, BAEROCIN and BAEROCID are registered trademarks of Baerlocher. For more information, please visit www.baerlocher.com. Press Contacts:

ROICOM

Stefan Horst

Tel: +49-151-12 72 63 62

E-Mail: s.horst@roicom.biz