KNF FLEXPAK Leverages Baerlocher’s BAEROPOL® T-Blends to Use 100%-Recycled Film and Achieve Cost-Effective Sustainability

Düsseldorf, Germany – October 18, 2019 – Baerlocher, a leading global supplier of plastics additives, announced here at K 2019 (Hall 5, Stand A21), that KNF FLEXPAK can now run 100 percent recycled film using post-industrial polyethylene (PE) film by improving its quality and consistency with Baerlocher’s BAEROPOL® T-Blend Resin Stabilizer. The Baerlocher technology resolved issues of variable film quality by preventing gels, bubble instability and haze that previously prevented KNF FLEXPAK, a U.S. custom packaging manufacturer, from incorporating post-industrial film in certain applications. In another successful trial, KNF FLEXPAK and Baerlocher partnered with EREMA, a leading manufacturer of plastic recycling equipment. EREMA successfully reprocessed film scrap stabilized with the BAEROPOL® T-Blend technology during testing at its facility in Ipswich, Mass.

“Thanks to the consistently high quality of the post-industrial film incorporating BAEROPOL® T-Blend stabilizer, we can now run 100 percent recycled material with confidence in its quality and consistency,” says Ray Glenn, sales director, KNF FLEXPAK. “Previously, we would have had to blend it with expensive prime material. Now, our production rate for recycled material is pretty much equal to prime. Further, since film lines can now run more efficiently and recycled materials can be used in higher-end products, our business has become more sustainable and cost-effective.”

Stabilizing Post-industrial Film

KNF FLEXPAK sought to increase the use of scrap from its film production processes in other applications but encountered quality problems. The blown film process subjects resin to high-shear/high-temperature conditions that can lead to degradation. Recycling this film without adding stabilizers can cause crosslinking, creating gels and variable melt flow that affect quality and processing. During trials, Baerlocher’s technical team identified BAEROPOL® T-1111 TX resin stabilizer as a prime candidate to help resolve these quality issues. BAEROPOL® T-Blends are blended synergistic polymer stabilizers that are pre-formulated to provide superior stabilization for most applications. They come in a variety of product forms (pastilles, rods, prills) and combine Baerlocher’s innovative Resin Stabilization Technology (RST) with various phenolic and phosphite stabilizers, imparting many benefits, including:

• Color stability

• Melt stability

• Reduces/replaces phosphites

• Acid scavenger prevents degradation

• Made from renewable, sustainable resources

• Easy-to-handle, dust-free solution

• 100 percent active product

• Compatibility with Generally Recognized as Safe (GRAS) applications

• Food contact approval Achieving Success with Recycled Film

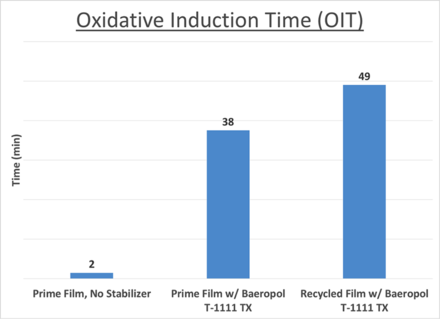

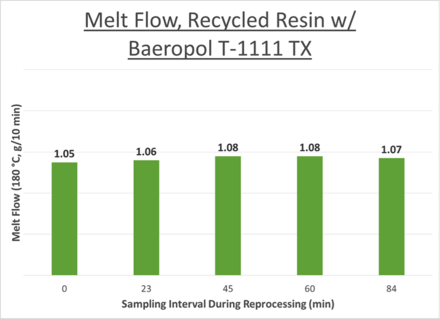

Testing according to ASTM D3895 – Standard Test Method for oxidative induction time (OIT) of Polyolefins by Differential Scanning Calorimetry (DSC) – showed that film produced with the T-Blend additive had significantly higher levels of stabilization than unstabilized film, contributing to the quality of the end product. Also, while recycled feedstock typically has high variation in melt flow, KNF FLEXPAK’s stabilized recycled resin shows remarkably stable melt flow values (± 1%). After achieving excellent quality reprocessed film with BAEROPOL® T-1111 TX, the team took an extra step by turning to state-of-the-art equipment. EREMA recycled the film scrap using its INTAREMA® 1108 TVEplus® system, adding a dose of BAEROPOL® T-1111 TX stabilizer to further improve quality. Testing for OIT showed this recycled film remained sufficiently stabilized to preserve quality in its next application. “As more manufacturers turn to post-industrial materials to achieve sustainability objectives for their customers and their own businesses, Baerlocher’s solutions make it easier to incorporate recycled content without sacrificing quality,” says Ian Query, technical specialist, Baerlocher USA. About Baerlocher:

The Baerlocher Group is a leading manufacturer of additives for the plastics industry. Its portfolio includes a broad range of stabilizers and other additives suitable for a variety of polymer and non-polymer applications. Baerlocher has a strong focus on customer and employee needs and is highly committed to innovation and sustainability. Its pioneering and proactive role is underlined by the support provided to the PVC industry during the transition from lead- to calcium-based stabilizers and by its innovative lubricant systems for wood plastic composites. Baerlocher embraces the principles of responsible care. It operates an ISO 9001 certified quality management system and an environmental management system compliant with ISO 14001. Baerlocher plays a positive role in both the business community and society as a whole. This includes work within industry associations, and the provision of training opportunities in a variety of disciplines. The Baerlocher Group has production plants around the globe and operates a sales network serving all major countries. BAEROPAN, BAEROSTAB, BAEROPOL, BAEROLUB and BAEROCID are registered trademarks of Baerlocher. For more information, please visit www.baerlocher.com. About KNF FLEXPAK:

As a custom manufacturer of film, bags, liners, sheeting, tubing, pouches and flexible packaging products, KNF FLEXPAK has been a leader in the extrusion and converter industry for Nylon and Polyethylene blown film for more than 25 years. The Nylon materials they manufacture used in the clean and ultraclean applications are strong and durable along with being manufactured with of the highest quality material available. Some of industry they provide product include; Food Service and Food Processing, Medical, Burial, Military, Industrial, Electrical, Pharmaceutical, Aerospace and Composite Industries. Stock and custom formulated blends are available for single wound sheeting, centerfold and tubing in various sizes, thickness and features. KNF FLEXPAK specializes in high temperature Nylon applications used for cooking and oven bags, pan-liners, solvent recovery, cook chill and vacuum bagging film. They continue to supply their customers with the latest in technology like their Microperfation produce bags called FRESHylon used to extend the shelf life of fruits and vegetable after picking and during transportation. Their professional sales managers and experienced internal personnel will provide the highest level of customer service available. For more information, please visit http://www.knfcorporation.com. Press Contacts:

The Americas

Roberto Nunez

Tel: +1-513-482-6304

E-mail: nunez.roberto@baerlocher.com The Americas Agency:

AH&M, Inc.

Joe Bennett

Tel: +1-413-448-2260, Ext. 470

E-mail: jbennett@ahminc.com Europe & Asia Agency:

ROICOM

Stefan Horst

Tel: +49-151-12 72 63 62

E-Mail: s.horst@roicom.biz

KNF FLEXPAK sought to increase the use of scrap from its film production processes in other applications but encountered quality problems. The blown film process subjects resin to high-shear/high-temperature conditions that can lead to degradation. Recycling this film without adding stabilizers can cause crosslinking, creating gels and variable melt flow that affect quality and processing. During trials, Baerlocher’s technical team identified BAEROPOL® T-1111 TX resin stabilizer as a prime candidate to help resolve these quality issues. BAEROPOL® T-Blends are blended synergistic polymer stabilizers that are pre-formulated to provide superior stabilization for most applications. They come in a variety of product forms (pastilles, rods, prills) and combine Baerlocher’s innovative Resin Stabilization Technology (RST) with various phenolic and phosphite stabilizers, imparting many benefits, including:

• Color stability

• Melt stability

• Reduces/replaces phosphites

• Acid scavenger prevents degradation

• Made from renewable, sustainable resources

• Easy-to-handle, dust-free solution

• 100 percent active product

• Compatibility with Generally Recognized as Safe (GRAS) applications

• Food contact approval Achieving Success with Recycled Film

Testing according to ASTM D3895 – Standard Test Method for oxidative induction time (OIT) of Polyolefins by Differential Scanning Calorimetry (DSC) – showed that film produced with the T-Blend additive had significantly higher levels of stabilization than unstabilized film, contributing to the quality of the end product. Also, while recycled feedstock typically has high variation in melt flow, KNF FLEXPAK’s stabilized recycled resin shows remarkably stable melt flow values (± 1%). After achieving excellent quality reprocessed film with BAEROPOL® T-1111 TX, the team took an extra step by turning to state-of-the-art equipment. EREMA recycled the film scrap using its INTAREMA® 1108 TVEplus® system, adding a dose of BAEROPOL® T-1111 TX stabilizer to further improve quality. Testing for OIT showed this recycled film remained sufficiently stabilized to preserve quality in its next application. “As more manufacturers turn to post-industrial materials to achieve sustainability objectives for their customers and their own businesses, Baerlocher’s solutions make it easier to incorporate recycled content without sacrificing quality,” says Ian Query, technical specialist, Baerlocher USA. About Baerlocher:

The Baerlocher Group is a leading manufacturer of additives for the plastics industry. Its portfolio includes a broad range of stabilizers and other additives suitable for a variety of polymer and non-polymer applications. Baerlocher has a strong focus on customer and employee needs and is highly committed to innovation and sustainability. Its pioneering and proactive role is underlined by the support provided to the PVC industry during the transition from lead- to calcium-based stabilizers and by its innovative lubricant systems for wood plastic composites. Baerlocher embraces the principles of responsible care. It operates an ISO 9001 certified quality management system and an environmental management system compliant with ISO 14001. Baerlocher plays a positive role in both the business community and society as a whole. This includes work within industry associations, and the provision of training opportunities in a variety of disciplines. The Baerlocher Group has production plants around the globe and operates a sales network serving all major countries. BAEROPAN, BAEROSTAB, BAEROPOL, BAEROLUB and BAEROCID are registered trademarks of Baerlocher. For more information, please visit www.baerlocher.com. About KNF FLEXPAK:

As a custom manufacturer of film, bags, liners, sheeting, tubing, pouches and flexible packaging products, KNF FLEXPAK has been a leader in the extrusion and converter industry for Nylon and Polyethylene blown film for more than 25 years. The Nylon materials they manufacture used in the clean and ultraclean applications are strong and durable along with being manufactured with of the highest quality material available. Some of industry they provide product include; Food Service and Food Processing, Medical, Burial, Military, Industrial, Electrical, Pharmaceutical, Aerospace and Composite Industries. Stock and custom formulated blends are available for single wound sheeting, centerfold and tubing in various sizes, thickness and features. KNF FLEXPAK specializes in high temperature Nylon applications used for cooking and oven bags, pan-liners, solvent recovery, cook chill and vacuum bagging film. They continue to supply their customers with the latest in technology like their Microperfation produce bags called FRESHylon used to extend the shelf life of fruits and vegetable after picking and during transportation. Their professional sales managers and experienced internal personnel will provide the highest level of customer service available. For more information, please visit http://www.knfcorporation.com. Press Contacts:

The Americas

Roberto Nunez

Tel: +1-513-482-6304

E-mail: nunez.roberto@baerlocher.com The Americas Agency:

AH&M, Inc.

Joe Bennett

Tel: +1-413-448-2260, Ext. 470

E-mail: jbennett@ahminc.com Europe & Asia Agency:

ROICOM

Stefan Horst

Tel: +49-151-12 72 63 62

E-Mail: s.horst@roicom.biz